PumaCRETE CUSTOMIZED ESD FLOORING SYSTEMS, for your BUDGET and APPLICATION

ESD FLOORING

Instead of a “one size fits all system”, we customize our anti static flooring materials to the customer’s specific application. PumaCRETE® ESD and conductive surfaces consistently meet customer’s operational needs, while exceeding expectations.

With a nationwide network of installers, PumaCRETE® has provided a tradition of quality. Our factory-trained installation crews can provide turn-key installation and localized service.

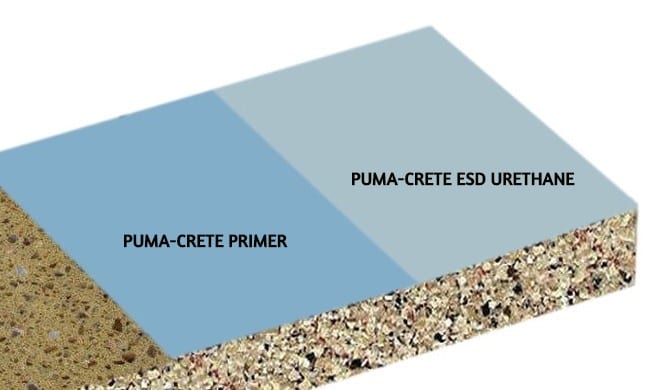

Epoxy and Urethane ESD Flooring

PumaCRETE® manufactures a complete line of static dissipative and static conductive epoxy and urethane flooring solutions, for our industrial, military and government customers. We feature the latest technology in ESD flooring and conductive floor systems. Through our local certified applicator network, we service clients throughout the U.S. and North America. If you need a turn key installation, click here.

TRAINING: PumaCRETE can provide on site trainers, along with detailed installation instructions and videos, specialty tools, and surface prep guidelines for new installers or DIY installation. See our installation page for our application resources.

COATING SYSTEMS High Performance thin mil and high build coating systems

THICKNESS

17 mils

17 mils

43 mils

43 mils

DESCRIPTION

3-coat, Anti Static, Coating System (static dissipative)

3-coat, Anti Static, Coating System (static conductive)

4-coat Anti Static, High Build Coating System (static dissipative)

4-coat Anti Static, High Build Coating System (static conductive)

RESURFACERS Covers over damaged substrates, and provides enhanced durability for manufacturing areas.

THICKNESS

1/8 to 3/16-inch

1/8 to 3/16-inch

1/8 to 1/4-inch

1/8 to 1/4-inch

DESCRIPTION

Heavy duty, Anti Static Resurfacer (static dissipative) MasterFormat Specifications

Heavy duty, Anti Static Resurfacer (static conductive) MasterFormat Specifications

Heavy duty, Anti Static Resurfacer for AGV/AMR areas (static dissipative) MasterFormat Specifications

Heavy duty, Anti Static Resurfacer for AGV/AMR areas (static conductive) MasterFormat Specifications

HIGH PERFORMANCE ANTI STATIC TOP COATS (for renewing floors after 5 to 10 years- for fraction of the cost of a new floor)

3 mils

3 mils

Dissipative urethane high performance top coat for anti static systems.

Conductive, high performance urethane top coat for PumaESD systems.

SPECIALTY INDUSTRY SECTORS

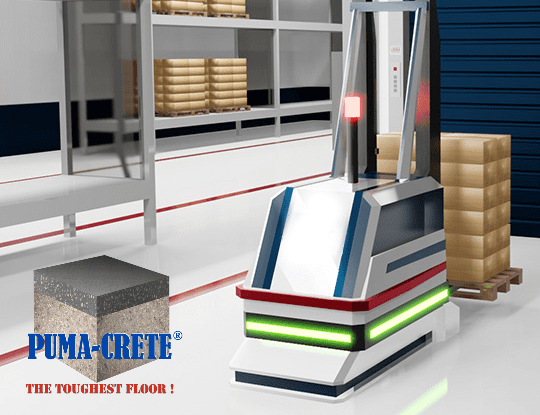

AGV (automatic guided vehicles) and AMR (autonomous mobile robot) Flooring

HIGH BUILD ANTI STATIC COATING SYSTEMS

201-c AGV PumaESD Conductive, high build, 40-50 mil anti static system, designed for AGV or AMR areas.

201-d AGV PumaESD Dissipative, high build, 40-50 mil anti static system, designed for AGV or AMR areas.

RESURFACERS

301-c AGV PumaESD 1/8 to 3/16 inch, static conductive, heavy duty, urethane resurfacer system. Enhanced reliability for wheeled vehicles.

301-d AGV PumaESD 1/8 to 3/16 inch, static dissipative, heavy duty, urethane resurfacer system. Enhanced reliability for wheeled vehicles.

HAZARDOUS ENVIRONMENTS - CONDUCTIVE FLOORING and STATIC ELECTRICITY HAZARDS

The potential hazard of static electricity arises when an accumulated electrical charge subsequently discharges as a spark in the presence of hazardous atmospheres, flammable vapors, dusts, exposed sensitive explosives, or EEDs.

ESD ignition sensitivity may vary depending on variations within the process. These hazards can develop from unpackaged detonators, primers, and EEDs. Additional product such as electrically initiated items, such as rockets, with exposed circuits, and any hazardous materials capable of initiation by ESD from the human body.

RESUFACER: help to fill in low areas, and provide a flatter surface for wheeled vehicles. This systems covers over damaged substrates and provides enhanced durability.

301-c AGV PumaESD 1/8 - 3/16 inch, heavy duty, urethane resurfacer system. STATIC CONDUCTIVE

We have a diverse customer base. Some of our customers include… IBM, Spectrum, Foxconn, NASA, Swemco, U.S. Navy, US Air Force, ATK, Northrop Grumman, Colorcon, General Dynamics, Spectra Technologies, Dupont, GE, Lutron, Scaled Composites, Johnson Space Center, Elanco (Eli Lilly), Charter Communications, Kongsberg Systems and many more...

"With a tradition of quality and durability, we have over 30 years of experience serving the needs of our customers -- we have the experience you can rely on!"