401-HFB® pumaCRETE is a 3/16 to 1/4 inch seamless urethane concrete floor. This is a heavy duty floor, with excellent resistance to abrasion and other physical aggression. It may be used in all heavy duty manufacturing environments. This includes food and beverage processing floors, as well as dry processing and other industrial manufacturing floors.

Additional features include: resistance to aggressive chemicals, wet conditions, and thermal shock. It maintains a slip resistant finish which never wears off (texture can be customized as needed).

Formulated to be applied as a slurry, and then quartz silica broadcasted floor, it is applied by cam rake or trowel.

SELECT YOUR APPLICATION BELOW

FOOD Processing Floors

BEVERAGE Processing Floors

INDUSTRIAL Manufacturing Floors

PumaCRETE ECO® is an extra heavy duty seamless, troweled urethane mortar. Applied at 1/4- 1/2 inch thickness, it was developed for the ultimate durability in punishing environments.

Since It is a "one pass" system, it can restore badly worn concrete surfaces in as little as one day. It withstands heavy traffic loads including heavy wheeled carts and fork trucks. Push, pull, drag or drop on this floor…. it is difficult to damage this beast. Fast curing, it can handle heavy cart traffic in as little as 12 hours at 70 deg F.

Typically applied by screeding (using screed box , screed bar or trowel), and then finished by hand troweling.

SELECT YOUR APPLICATION BELOW

401-ECO® Technical Data Sheet

401-ECO pumaCRETE in USPS Workrooms

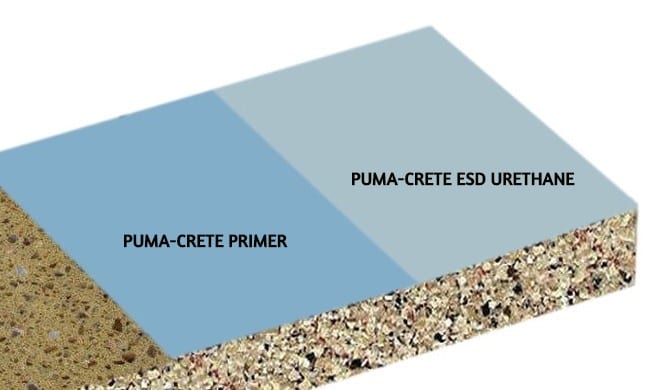

PumaCRETE® has a complete line of ESD and conductive flooring systems. The products include thin film coating systems, hi-build coating systems, and heavy duty toppings. All versions feature a three-component, chemical-resistant, aliphatic polyester ESD urethane top coat.

Systems are available in conductive (C) or static dissipative (SD) versions, and feature reliable electrostatic control properties.

Features include a highly cleanable surface, color and gloss retention. PumaCRETE ESD® floors exhibit a non-yellowing, semi-gloss to satin finish and are available in a variety of colors and textures.

SELECT YOUR APPLICATION BELOW