100/200 SERIES

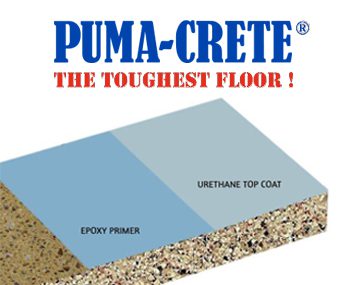

PumaCRETE® 100 series coatings are individual products. A complete coating system, which is a cost-effective light to medium duty solution for your concrete floors in new or "like-new" condition. They are primarily used in dry environments and provide long-lasting protection for your concrete. These multi-layered coating systems provide excellent protection of your facility floor, with an attractive and easy-to-clean finish.

TRAFFIC CONDITIONS EXPECTED

Foot, cart, and occasional power lift usage.

THICKNESS

12 to 60 mils thickness (.012 to .060 inch).

HIDING POWER

Increased hiding power for concrete surface defects for renovation.

FINISH

Satin to gloss.

APPLICATION

Spread with flat or serrated (v-notch) squeegee and rolled with 9 and 18-inch paint rollers. These floors will have excellent abrasion resistance for foot and cart traffic, as well as rubber-wheeled power lift traffic.

OTHER ADVANTAGES

1. Good all-around chemical resistance (we can customize for more aggressive chemicals).

2. Customized texture (from smooth as glass to very rough and in between).

3. Easy to clean, nonporous finish.

—

Learn more about Industrial Manufacturing Floors

300 SERIES

PumaCRETE 300® Series is are urethane concrete floor system, customized to your application. They consist of a tough urethane cement base coat with a polymeric top coat or lock coat. The 300 series systems have all-around durability for most heavy-duty industrial traffic conditions. They also offer increased hiding power for concrete surface defects (holes, cracks, rough areas) often found in renovation projects.

TRAFFIC CONDITIONS EXPECTED

Maximum durability for the most abusive environments. Increased thickness increases durability for impact, scraping, and gouge resistance.

THICKNESS

1/16 to 1/4 inch

HIDING POWER

Increased hiding power for concrete surface defects for renovation.

FINISH

Satin to gloss.

APPLICATION

Applied with a combination of serrated (v-notch) squeegee(s) and optional cam or pin rake.

OTHER ADVANTAGES

1. Tolerance to damp and wet conditions

2. Thermal shock resistant

3. Good all-around chemical resistance (may be customized for more aggressive chemicals).

4. Texture may be customized for your needs (from smooth as glass to very rough and in between).

5. Easy to clean, nonporous finish.

—

Learn more about Food & Beverage Floors

Learn more about Industrial Manufacturing Floors

⊕ 301-SLB Specifications

⊕ 301-SL Specifications

⊕ view color chart

400 Series

PumaCRETE® 400 series is are extra heavy-duty, seamless system. Known as a hand-troweled urethane mortar or screed. Applied at 1/4- 1/2 inch thickness, these were developed for the ultimate durability in punishing environments.

TRAFFIC CONDITIONS EXPECTED

Maximum durability for the most abusive environments.

THICKNESS

1/4 to 1/2 inch

HIDING POWER

Increased hiding power for concrete surface defects for renovation.

FINISH

Matte/flat. May be waxed for a high-gloss appearance.

APPLICATION

Spread and finish with a concrete finishing trowel -one pass application. (option: spread with rake or screed box)

Since it is a "one-pass" system, it can restore badly worn concrete surfaces in as little as one day. It withstands heavy traffic loads, including heavy wheeled carts and fork trucks.

Push, pull, drag, or drop on this floor…. It is difficult to damage this beast. Fast curing as well, these floors can handle heavy cart traffic in as little as 12 hours at 70 degrees F.

—

⊕ 401-ECO PumaCRETE in USPS Work Rooms

⊕ 401-ECO® Specifications

⊕ view color chartt

Puma-ESD Series

PumaCRETE® has a complete line of ESD and conductive flooring systems from the 100 to 400 series, called PumaESD. The products include thin film coating systems, hi-build coating systems, and heavy-duty toppings. These systems are customized for the specific needs of each customer. Typical usage includes electronics manufacturing and storage, AGV and AMR areas, as well as munitions and hazardous volatile chemical processing and storage. Versions feature a four-component, chemical-resistant, aliphatic polyester ESD urethane top coat.

PumaESD Systems are available in conductive (C) or static dissipative (SD) versions and feature reliable electrostatic control properties.

TRAFFIC CONDITIONS

Options are available for all traffic conditions.

THICKNESS

Applied from 12 mils to 1/4 inch

HIDING POWER

Thicker systems provide enhanced hiding of concrete surface defects.

FINISH

Satin to semi-gloss

APPLICATION

Applied with a serrated (v-notch) squeegee(s) and optional cam or pin rake.

OTHER ADVANTAGES

1. Highly cleanable, stain-resistant surface

2. High abrasion resistance (additional wear-resistant system available for extreme abrasion areas such as AGV, high traffic warehouses, etc.)

3. Color and gloss retention (resistant to yellowing from UV light).

4. Good all-around chemical resistance (may be customized for more aggressive chemicals).

5. Customized texture (from smooth as glass to very rough and in between).

6. PumaCRETE PumaESD® floors exhibit a non-yellowing are available in a variety of colors.